|

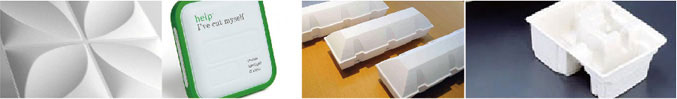

Pulp, vegetable fibers, or even waste paper can be the raw material, depending on the functional requirements into various shapes of products, after a good mold design makes a good buffer function. By adding anti-bacterial agents, anti-static electricity, enhancer and other materials adjust the needs of the majority product packaging, along with the environmental and aesthetic features.

Molded paper pulp packaging and traditional plastic packaging have the similar performance on shock resistance, anti-static, stackable, bio-degradable this feature is better than traditional cushioning materials.

Molded paper pulp packaging products can be widely used in electronics, electrical appliances, communications lined packaging, with its excellent environmental character, brings out the product value, and gradually replace Styrofoam and plastic packaging.

The characteristics of Molded Paper Pulp Packaging:

- Excellent buffer and shock resistance

- Delicate quality, no deckle edge or wrinkle appearance.

- Cut down the packaging process labor hour

- ISO 14000 standards approved.

- Flexible of the material with diversity usage

- No waste water and wastes during manufacturing.

- Additives may added as required. Molded pulp products is the new packaging materials, an excellent alternative to the plastic product.

Usage of paper pulp packaging:

Molded pulp products is restricted to be inclusive as solid container, storage and transportation services in the flow of goods with other sectors that are mainly used in the transport packaging.

Molded Pulp Product, Paper Food Packaging Functions:

Molded paper pulp products feature: inclusive and protective for the packaged products, convenient and practical.

Inclusive and protective packaging products is the primary function of molded pulp products. Molded pulp products should be able to rely on accommodate packaging requirements of the packaged products, packaging products that are in the transportation, handling, use of the process from damage and to meet their own strength, stiffness and stability requirements.

Molded pulp products through its own special structure of the variability in the load by the appropriate time to extend, absorb external energy, which reduce the packaging by shock and vibration. It is different from the Styrofoam buffered packing, because the Styrofoam with a large number of internal distribution of compressible foam, regardless the shape of the products, it has good buffer properties, so the good molded pulp design may complete protect the contents in the shipping and handling process and also improve shock absorption capacity of the basic approach. Structural design packages can directly affect the strength, stiffness, stability and practicality.

|